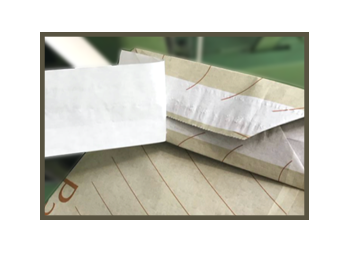

During this process, overlapped plies of different materials are glued together (paper + paper, HDPE + paper, etc).

BAG & SACK MANUFACTURING

Inline Seam-Longitudinal Gluing on Tuber Machines

INLINE SEAM-LONGITUDINAL GLUING ON TUBER MACHINES

Our electronic glue system, consisting of 1, 2, 3 or more valves (configuration varies according to the number of plies), replaces the existing, inefficient glue wheel systems.

ERO electronic gluing systems replace the previous glue pots allowing significant glue savings. Furthermore, they allow extremely precise glue application and dot adjustment.

-

No glue disposal problems

-

Accurate glue dosage

-

Dot mode application for glue savings

-

Easy programming

-

Low maintenance

Electronic guns can apply in dot mode to save adhesive while maintaining the bonding.

Electronic guns replace the old and messy glue pots, reducing maintenance and saving glue.

ERO Electronic gluing systems reduce your glue disposal needs and allow important glue savings at the time they reduce downtime and maintenance.

Learn more about the benefits that ERO technology can bring to your production line and download the complete booklet.