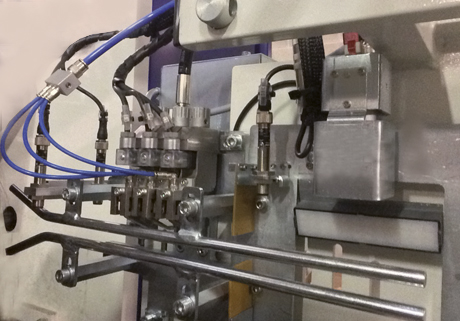

ERO-OC glue inspection system is controlled from a 12“ touch screen control or iPad, which provides real-time images of the production line, and can also display pictures of the last faulty box detected, for an in-depth gluing defect analysis. The system takes a picture of each box produced, up to 200 photos of faulty boxes can be saved. A data analyzer, encoder frequency divisor and stroboscopic illuminator are installed within an electrical cabinet.

ERO-OC

Extra-High Speed Glue Inspection Camera

The control station is supplied with the following as standard:

- Black & white camera.

- Maximum speed: 350 m/min.

- 128 high-efficiency LED stroboscopic camera illuminator.

- Right side support for camera and illuminator OR left side support for camera and illuminator.

- Illuminator driver.

- Encoder divider.

- Marker driver.

- Low noise and 5 meters of protected camera cable.

- 5 meters of illuminator cable.

12" Touch Screen or Ipad Control

12" Touch Screen or Ipad ControlTechnical Features

-

100% Glue control guaranteed for every type of color and format

-

Pictures are taken and shown in real time

-

Leading technology, fully compatible with the majority of glue systems

-

Complete report of production can be saved and printed

-

Easy handling

- Smallest readable dot = Ø1.5 at 200 meters/minute.

- Adjustable tolerance threshold to measure if glue levels are too low or too high.

- Adjustable tolerance threshold for shifted glue pattern position at the beginning or at the end of glue patterns (Min. tolerance = 1 mm).

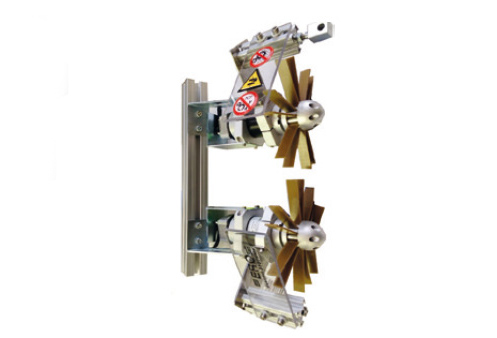

ERO-ETR Tab-Trim Removal System

ERO-ETR removes tab trim and scrap before they reach the glue station.